Bangladesh, as a high leather producing country, has always received a rather negative coverage from the press and media – primarily due to concerns about environmental pollution and lack of standards. Back in 2015, as I first began working in the leather industry, my naivety led me to also assume that Bangladesh was a high-risk sourcing option for brands; after all, that’s what I was told and that’s what I read, so it must be true, right? Of course, as my experience grew, my realisation that this kind of generalisation is not only ignorant but also damaging for the leather industry as a whole, really cemented within me a desire to support positive change and raise visibility of the good that is being done alongside the challenges to be worked on.

So, with that in mind, I first want to clearly say, without minimising the scale of the challenges, that in order to become and remain sustainable for the long term the leather industry needs to drive change throughout the value chains by leveraging opportunities. The industry should actively work together to drive forward the long-term transformative change that is necessary across a number of areas within our remit.

During my last 6 years in the industry, I have visited tanneries in the UK, France, Italy, Portugal, India, North America, Brazil, Argentina and Bangladesh. I have seen great tanneries, I have seen OK tanneries and I have seen bad tanneries, but I cannot say that all the good tanneries are in one country and all the bad tanneries are in one country. This is such an important truth to be taken onboard by brands, consumers, media and other fellow leather manufacturers – there are good and bad tanneries in every country around the world and the sooner we start from that basic truth, the better off we will be as an industry.

Bangladesh International Investment Summit

Reflecting now on my recent visit to Bangladesh, the principal purpose of the trip was an invitation from the Prime Minister’s Office to take part in the technical session on Leather & Leather Goods, as part of the Bangladesh International Investment Summit on 28-29th November 2021. This 2-day event was focused on the promotion of Bangladesh as one of the world’s most profitable investment destinations, and to attract private investment. The Leather & Leather Goods session was one of 11 dedicated sessions for sectors that are key for the country’s economic success.

The leather industry is one of the oldest in Bangladesh and is the country’s second largest export revenue earner after ready-made garments. Bangladesh has a strong local supply of high-quality resources (including a motivated workforce) and has a huge growth potential for the export of high-quality leather and leather goods. However, as is often the case with developing countries, the pace of improvement necessary to stay in line with global expectations when it comes to sustainability is not always fast enough, especially when significant and self-sufficient upskilling, training and knowledge needs are required, coupled with investment in technology and infrastructure.

During the technical session, the potential for growth was clearly outlined along with the challenges that would need to be overcome in order to achieve that potential. While a lot of the conversation was concerned with logistics and taxation, it was incumbent to clearly emphasise that along with huge potential for growth comes an equal potential for increasing the environmental pollution that will continue to happen until the malfunctioning CETP at Savar is corrected.

During my intervention, I offered a 2-part solution to changing the global perception of Bangladesh as a source of sustainably produced, high-quality leather:

Part 1:

the tanners themselves must start to address their responsibilities for good practice for all elements that sit within their direct control. It is no longer acceptable for them to abdicate responsibility entirely to the CETP issue. Tanners in Bangladesh need to do their part to ensure that they reduce as much potential for pollution as possible within their area of influence.

Part 2:

the CETP at Savar cannot be left as a malfunctioning reminder of the failure of the relocation from Hazaribagh to Savar. Government, private sector, NGOs and other stakeholders have to work together to find a corrective plan that will support these tanneries by giving them a working treatment plant as they were promised. This requires the appointment of a credible effluent engineer with a proven track record in leather wastewater treatment, who is independent of any affiliation to government officials and who is recognised internationally as a credible party. A published action plan with timeframes against which accountability is measured is necessary to ensure deliverables are achieved.

The discussion both during and after the sessions left a sense of renewed optimism for approaching the challenges in a different way. The Sustainable Leather Foundation’s A.I.M. approach to improvement (Accessibility, Inclusivity and Modularity) works perfectly for tanneries who are unable to get recognition at international level due to the failing CETP. The SLF Transparency Dashboard allows them to gain certification and recognition of all of the conformance that they do meet while clearly identifying the areas that are still not under control (such as the CETP).

Crucially though, we must not forget that there are tanneries in Bangladesh that are not connected to the Savar CETP and that do already meet high international standards for environmental, social and governance performance.

Tannery and Product Manufacturing Visits

Apex Footwear: Well known for leading the way for the leather industry in Bangladesh, Apex Footwear has been a medal rated member of LWG since 2015 and prides itself on being a company that seeks to work in as sustainable a way as possible. Visiting both the production site and the tannery in the Gazipur District of Dhaka was a confirmation of what I expected, a professional, well run and efficient operation. The meeting spaces would not be out of place in any of the fashion centres around the world and the staff were welcoming and experienced in their knowledge and understanding of what was required of a sustainable business.

Apex Footwear enjoys the fortune of having its own effluent treatment plant (ETP), a possibility that is not there for the vast majority of tanneries.

Apex Tannery: This is a tannery that was forced to relocate from Hazaribagh to Savar and is therefore obliged to discharge into the failing central effluent treatment plant (CETP). Although Apex Footwear and Apex Tannery have independent management structures, they do apply the same processes, procedures and ethics, working as sustainably as possible, and this is where I start to see basic flaws in the historic way of assessment. One facility enjoys a global presence accepted for meeting international standards; the other can’t get any recognition because it is located in the Savar district and is forced to discharge its wastewater to the malfunctioning CETP.

Whilst the treatment of the effluent is a high priority and concern, it is just one of a multitude of elements to be considered in the safeguarding of people, planet and profit. Where is the recognition of the other good practice? Why does one failing element that is outside of the control of a tannery mean that they cannot operate on the international stage with recognition of the rest of their standards which in some cases are higher than other facilities?

This is one of the reasons for the SLF Transparency Dashboard approach – through SLF it is possible for the tannery to demonstrate all the good work being done within its control whilst recognising the shortfall of the effluent treatment currently.

It is worth noting here that Apex Tannery have now secured permission to build their own ETP and hope to be able to start that work soon. This shouldn’t have been necessary, had the Savar CETP been fit for purpose, but Apex recognise that they cannot continue indefinitely without being able to responsibly treat their effluent.

Bay Tannery: Another interesting visit to another well run, clean, professional tannery – this facility is once again in the Savar tannery district and as such is forced to discharge to the malfunctioning CETP.

As with Apex, Bay have also secured permission to build their own ETP and I was shown the land that has been cleared and reserved for the proposed construction.

In a twist of irony, although both these tanneries are committed to make the necessary investment to build their own ETPS, and although permission has been granted, neither facility yet has permission to discharge directly to the environment.

How ironic would it be if the cleaned wastewater from these tanneries still had to ultimately discharge into the failing CETP? These are the issues that must be resolved, and common sense must prevail when decisions are taken in this regard.

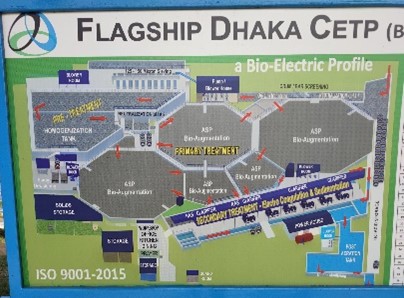

Austan: Austan is located in the EPZ (Export Processing Zone) region of Dhaka and discharges into a CETP that was a real surprise to see. Adjacent to the tannery, this CETP is run by Flagship and I was given a tour of the plant by the operators. This was a revelation! The Flagship CETP was an example of what is possible. I was left a little shocked that this well maintained, efficient plant was in existence and situated just miles from the Savar failure.

I enjoyed the tour of the CETP which was given by a very knowledgeable and experienced technician who was open and informative, and it restored my belief that with some commitment from the ministerial departments of government, the Savar plant could be turned around. Indeed, I know first-hand that there are companies who have the necessary expertise and who are willing to work with the government and tanners to solve the issue.

With all 3 tanneries I saw some good quality leather being produced for both the domestic market and the international export market – it was a shame that there wasn’t more time to visit the other tanneries that requested meetings, but I am sure there will be opportunity during my next trip!

Turning now to the Product Manufacturing Facilities:

Picard: Manufacturing leather goods for export to Australia and Germany, this was an organisation that holds social responsibility as a key priority. While all the product manufacturing facilities I visited had medical centres, nurseries and canteens, Picard has a community school that is not only for the benefit of children of employees but also for the local community. I paid a brief visit to the school, and it was joyful to see this place of learning opportunity.

Within the factory itself, the quality of the goods, the professionalism of the workforce and the sense of community was clearly evident.

Bay Footwear: This was a Bangladesh facility run by Chinese management and servicing many well-known brands. Investment and improvement to the facility was evident but here I was struck by another phenomenon; all of the production here was using specified leather from leather manufacturers outside of Bangladesh. So leather was being imported by the brands to be used for the production of the footwear – no locally produced leather was being used. We know that the reason for this is reputational risk for the brands, but how sustainable is this really?

Which leads me to another irony; in order to meet the demands of brands that specify a certain certification programme, a tannery is forced to import wet blue or crust material from overseas just to score enough points on a system. How can this be in the best interest of:

(a) the tannery – being forced to pay more money for incoming material supplies and not be able to support their local economy?

(b) the local country – knowing they have an abundance of raw material and not being able to sell it locally?

(c) the planet – the carbon footprint on the transportation of the material from halfway around the world is not beneficial to environmental footprint and from any perspective must be counter-intuitive to what we all say we want to protect against?

FB Footwear: The facility at FB Footwear was another example of an efficient and well-run product manufacturing facility. Walking around the factory, and in keeping with the other facilities, I was struck by the welcoming nature of the workforce. The facilities were bright, well ordered and offered a community feel.

It was also good to see that these facilities have accreditation with reputable organisations and certification programmes including Satra and ISO standards, showing a commitment to healthy workplaces and happy workers. The leather used at FB Footwear is a mix of locally sourced and imported.

Finally, I also managed to squeeze in a visit to the offices of the Leathergoods and Footwear Manufacturers & Exporters Association of Bangladesh (LFMEAB). It was a great opportunity to learn more about the excellent work they are doing in raising standards amongst their members and I’m looking forward to strengthening links with the associations and organisations in Bangladesh in order to support the development work locally.

My visit to Bangladesh was valuable on so many levels and I thank everyone who made the trip possible and took the time to welcome me into their facilities. It was a pleasure to meet so many people who are all working for a better leather industry.

Do I think the Bangladesh leather industry has potential? Yes. Do I think it’s ready to maximise that potential? No, not yet, but it could be with the right support and more emphasis on getting some foundational aspects like the CETP at Savar corrected.

As a closing note, I would ask brands to start really evaluating what their priorities are when considering true sustainability. Notwithstanding the CETP issue which needs to be addressed as an urgent priority, working in partnership and building strong relationships with suppliers in Bangladesh could be a credible and sustainable choice for the future and I already know of a number of brands who are doing exactly this – working with their suppliers for long term success and sustainability.